Introduction

The demand for high-quality, durable, and cost-effective construction materials is on the rise in Kenya. Among the most innovative and practical solutions available today are precast paving hollow blocks in Kenya. These blocks offer superior strength, versatility, and ease of installation, making them ideal for road construction, parking lots, pedestrian walkways, and landscaping projects.

MOTHERLAND CONCRETE & LOGISTICS is a trusted provider of precast paving hollow blocks in Kenya, offering reliable, high-quality solutions for developers, contractors, and homeowners. With a commitment to durability and efficiency, the company ensures that its paving blocks meet industry standards while remaining affordable.

In this article, we will explore the benefits, applications, and advantages of using precast paving hollow blocks in Kenya and why MOTHERLAND CONCRETE & LOGISTICS is the go-to supplier for quality precast products.

What Are Precast Paving Hollow Blocks?

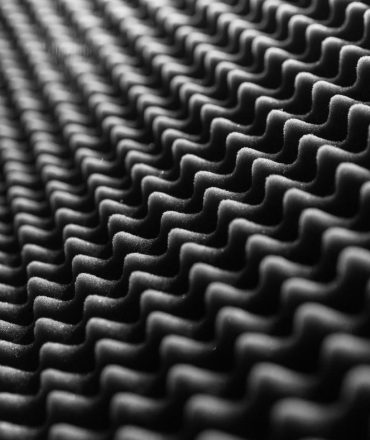

Precast paving hollow blocks in Kenya are factory-made concrete blocks designed for outdoor paving applications. Unlike traditional paving methods, precast blocks are manufactured under controlled conditions, ensuring uniformity, strength, and durability.

These blocks feature a hollow design, which reduces material usage while maintaining structural integrity. Their lightweight nature makes them easy to handle and install, making them a preferred choice for both large-scale and small-scale paving projects.

MOTHERLAND CONCRETE & LOGISTICS produces high-quality precast paving hollow blocks in Kenya, ensuring that they meet both aesthetic and functional requirements for different paving needs.

Advantages of Using Precast Paving Hollow Blocks in Kenya

Choosing precast paving hollow blocks in Kenya offers several advantages over conventional paving solutions:

1. Durability and Strength

These blocks are manufactured using high-strength concrete, making them highly resistant to wear, weathering, and heavy traffic loads. They provide long-lasting performance, reducing the need for frequent repairs and replacements.

2. Cost-Effectiveness

Compared to poured-in-place concrete, precast paving hollow blocks in Kenya are more affordable due to reduced labor costs, minimal material wastage, and faster installation. MOTHERLAND CONCRETE & LOGISTICS ensures that customers get high-quality blocks at competitive prices.

3. Ease of Installation

Precast blocks are designed for quick and hassle-free installation. Their interlocking design ensures stability and eliminates the need for extensive site preparation, making them an excellent choice for time-sensitive projects.

4. Eco-Friendly and Sustainable

Using precast paving hollow blocks in Kenya reduces environmental impact. They require less cement and raw materials, and their hollow design enhances water drainage, preventing flooding and erosion in paved areas.

5. Low Maintenance

Once installed, these blocks require minimal maintenance. They resist cracking, chipping, and fading, ensuring a long-lasting and visually appealing finish.

Applications of Precast Paving Hollow Blocks in Kenya

The versatility of precast paving hollow blocks in Kenya makes them suitable for various applications. MOTHERLAND CONCRETE & LOGISTICS supplies these blocks for multiple construction and landscaping projects, including:

1. Road and Highway Paving

Precast blocks provide a stable and durable surface for roads, reducing the need for costly asphalt or concrete paving. Their strength makes them ideal for high-traffic areas.

2. Parking Lots

Commercial and residential parking lots benefit from the durability and ease of maintenance of precast paving hollow blocks in Kenya. Their permeability also helps manage rainwater runoff effectively.

3. Pedestrian Walkways and Sidewalks

Urban areas, parks, and commercial zones use precast paving blocks to create safe, visually appealing walkways that are resistant to wear and tear.

4. Landscaping and Outdoor Spaces

These blocks are popular for driveways, patios, and garden paths due to their aesthetic appeal and ability to blend with different landscaping designs.

5. Industrial and Commercial Facilities

Warehouses, loading docks, and industrial zones require durable surfaces that can withstand heavy machinery and frequent use. MOTHERLAND CONCRETE & LOGISTICS provides strong precast solutions for such environments.

The Manufacturing Process of Precast Paving Hollow Blocks

Producing precast paving hollow blocks in Kenya involves a detailed process to ensure quality and durability. MOTHERLAND CONCRETE & LOGISTICS follows strict manufacturing protocols, including:

1. Selection of Raw Materials

High-quality cement, aggregates, sand, and water are carefully selected to achieve optimal strength and durability.

2. Mixing and Molding

The materials are mixed in precise ratios before being poured into pre-designed molds. The hollow sections are formed to ensure reduced weight without compromising strength.

3. Curing and Drying

The blocks undergo a controlled curing process to enhance their durability and resistance to environmental conditions.

4. Quality Control and Testing

Each batch of precast paving hollow blocks in Kenya is tested for compressive strength, uniformity, and dimensional accuracy to ensure compliance with industry standards.

By following these rigorous steps, MOTHERLAND CONCRETE & LOGISTICS guarantees high-performance paving solutions.

Why Choose MOTHERLAND CONCRETE & LOGISTICS for Precast Paving Hollow Blocks in Kenya?

When it comes to sourcing precast paving hollow blocks in Kenya, MOTHERLAND CONCRETE & LOGISTICS stands out for several reasons:

- High-Quality Products – The company ensures that all paving blocks meet strict quality standards for durability and performance.

- Affordable Pricing – Customers benefit from competitive prices without compromising on quality.

- Fast and Reliable Delivery – With an efficient distribution network, orders are delivered on time, reducing project delays.

- Expert Consultation – The team offers guidance on the best paving solutions based on specific project needs.

- Commitment to Sustainability – The company adopts eco-friendly manufacturing practices to minimize its carbon footprint.

By choosing MOTHERLAND CONCRETE & LOGISTICS, customers get reliable and long-lasting precast paving hollow blocks in Kenya for their construction projects.

Installation Tips for Precast Paving Hollow Blocks in Kenya

To ensure a successful paving project, follow these installation tips:

- Prepare the Site Properly – Clear debris, level the ground, and compact the soil before installation.

- Use a Stable Base Layer – A well-compacted base of gravel or sand provides a strong foundation for the blocks.

- Ensure Proper Alignment – Place the blocks carefully to maintain uniform gaps and a neat finish.

- Compact and Secure the Blocks – Use a mechanical compactor to lock the blocks in place and prevent shifting.

- Apply Joint Sand and Sealant – Filling gaps with fine sand and sealing the surface enhances durability and weather resistance.

Following these steps guarantees a professional and long-lasting installation of precast paving hollow blocks in Kenya.

Conclusion

Investing in precast paving hollow blocks in Kenya is a smart decision for anyone looking for durable, cost-effective, and visually appealing paving solutions. Whether for roads, walkways, parking lots, or landscaping, these blocks offer unmatched strength and ease of installation.

MOTHERLAND CONCRETE & LOGISTICS is a trusted supplier of high-quality precast paving hollow blocks in Kenya, providing reliable products tailored to various construction needs. With a focus on quality, affordability, and sustainability, the company ensures that every project benefits from superior paving solutions.

For the best precast paving hollow blocks in Kenya, contact MOTHERLAND CONCRETE & LOGISTICS today and transform your paving projects with durable and efficient precast solutions.