When it comes to constructing robust and reliable flooring systems, beam and block floors have become a popular choice among builders and architects. This versatile and efficient method of flooring offers numerous advantages, making it a go-to solution for a wide range of construction projects. In this article, we will explore the characteristics, benefits, and considerations of beam and block floors.

Understanding Beam and Block Floors

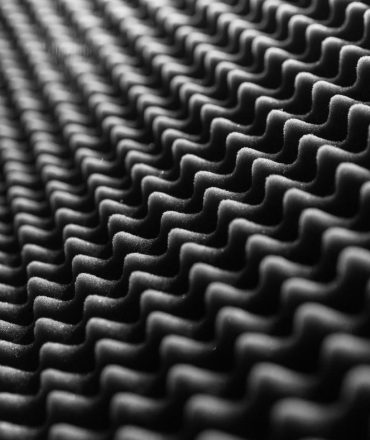

Beam and block floors consist of precast concrete beams laid across the span of a building, supported by precast concrete blocks placed between the beams. This method creates a strong, load-bearing structure that forms the foundation for subsequent building phases. The blocks typically have hollow cores, providing a balance between strength and weight.

Advantages of Beam and Block Floors

1. Rapid Installation:

One of the primary benefits of beam and block floors is the speed of installation. The precast components can be quickly laid out and assembled, reducing construction time compared to traditional methods. This rapid installation not only accelerates the overall building process but also allows for quicker progression to subsequent stages of construction.

2. Cost-Effective:

Beam and block floors are often more cost-effective than alternative flooring solutions. The precast elements are manufactured off-site, reducing labor costs associated with on-site construction. Additionally, the speed of installation can contribute to overall cost savings, making this method an attractive option for budget-conscious projects.

3. Design Flexibility:

This flooring system offers a high degree of design flexibility. The precast beams and blocks come in various sizes, allowing architects and builders to tailor the floor layout to specific project requirements. This adaptability makes beam and block floors suitable for a wide range of building types, from residential homes to commercial structures.

4. Thermal Efficiency:

The hollow cores of the precast blocks provide natural insulation, contributing to the thermal efficiency of the building. This insulation can help regulate indoor temperatures, reducing the reliance on additional heating or cooling systems. As a result, beam and block floors contribute to energy efficiency and environmental sustainability.

5. Structural Integrity:

Beam and block floors are renowned for their structural integrity and load-bearing capacity. The interlocking components create a stable framework capable of supporting heavy loads, making them suitable for multi-story buildings. The robust nature of this flooring system enhances the overall durability and longevity of the structure.

6. Minimal Site Disruption:

Since the components are manufactured off-site and delivered when needed, beam and block floors minimize on-site disruption. This can be particularly advantageous in urban or densely populated areas where noise and construction activities need to be carefully managed. The reduced on-site construction time also contributes to a quieter and more efficient building process.

Considerations and Challenges

While beam and block floors offer numerous advantages, it’s essential to consider factors such as site conditions, load requirements, and local building regulations. Proper installation and attention to detail are crucial to ensuring the long-term performance of the flooring system. Additionally, coordination with other construction elements, such as walls and columns, is essential for seamless integration.

Considerations:

1. Site Conditions:

- Ground Conditions: The ground conditions at the construction site play a crucial role. The load-bearing capacity of the soil must be assessed to ensure it can support the weight of the beam and block floor system.

- Drainage: Adequate drainage is essential to prevent water accumulation beneath the floor, which could lead to issues such as dampness and structural problems.

2. Load Requirements:

- Structural Design: The design of the beam and block floor must account for the specific loads it will bear. This includes not only the weight of the structure but also factors like live loads and point loads from heavy furniture or equipment.

3. Building Regulations:

- Compliance: It is imperative to adhere to local building regulations and codes. Ensure that the chosen beam and block floor system meets all safety and structural integrity requirements mandated by regulatory authorities.

4. Coordination with Other Elements:

- Integration with Walls and Columns: Proper coordination with other structural elements, such as walls and columns, is essential for seamless integration. This ensures that the beam and block floor system aligns with the overall structure.

5. Insulation and Acoustics:

- Thermal Performance: While beam and block floors offer natural insulation, additional insulation materials may be required to meet specific thermal performance standards.

- Acoustic Considerations: Consider acoustic requirements, especially in multi-story buildings, to minimize sound transmission between floors.

6. Professional Installation:

- Skilled Labor: Proper installation of the beam and block system requires skilled labor. Ensure that the construction team is experienced in working with this flooring method to avoid issues during and after installation.

Challenges:

1. Height Restrictions:

- Floor-to-Ceiling Height: Beam and block floors may increase the overall floor-to-ceiling height. This can be a consideration in projects with height restrictions, especially in renovations or where existing structures are in place.

2. Services Integration:

- Routing Services: Integrating services such as plumbing and electrical within the floor structure can be challenging. Proper planning is needed to ensure services can be accommodated without compromising the structural integrity.

3. Handling and Transportation:

- Handling Precast Components: The precast beams and blocks are heavy, requiring careful handling and transportation. Adequate equipment and safety measures must be in place to avoid accidents during delivery and installation.

4. Expansion and Contraction:

- Temperature Variations: Like any concrete-based system, beam and block floors may experience expansion and contraction with temperature variations. Proper joint detailing and consideration for potential movement are crucial.

5. Cost Implications:

- Initial Cost: While beam and block floors can be cost-effective in the long run, there may be an initial cost consideration. The cost of precast components and skilled labor should be factored into the overall project budget.

6. Maintenance Requirements:

- Access for Maintenance: Consideration should be given to how maintenance tasks, such as accessing services beneath the floor, will be carried out without compromising the structural integrity.

Conclusion

Beam and block floors have proven themselves as a reliable and efficient solution for a variety of construction projects. With their rapid installation, cost-effectiveness, design flexibility, thermal efficiency, structural integrity, and minimal on-site disruption, these floors continue to be a preferred choice for builders and developers aiming to construct robust foundations for their structures. As the construction industry evolves, beam and block floors stand as a testament to the importance of innovative and practical solutions in building strong, enduring foundations for the future.