As environmental concerns grow, sustainable building materials are becoming more important in the construction industry. One key option gaining attention is eco-friendly hollow blocks. These blocks, used extensively in modern construction, are designed to reduce environmental impact while offering strength, durability, and energy efficiency. In this article, we’ll explore several eco-friendly hollow blocks options, their benefits, and how they contribute to sustainable building practices. We’ll also highlight Motherland Concrete Logistics, a leader in providing eco-friendly construction solutions.

What Are Eco-Friendly Hollow Blocks?

Hollow blocks are a common material in construction due to their durability and ease of use. Traditionally made from cement, sand, and aggregates, these blocks have a significant environmental impact due to the energy-intensive processes used in their production. However, eco-friendly hollow blocks are made with sustainable materials and methods, offering a greener alternative without compromising on quality.

Why Choose Eco-Friendly Hollow Blocks?

Opting for eco-friendly hollow blocks provides several advantages, both for the environment and for the building’s occupants. These include:

- Energy Efficiency: The hollow design improves thermal insulation, helping regulate indoor temperatures. This reduces the need for heating and cooling, leading to lower energy consumption and reduced carbon emissions.

- Durability and Strength: Eco-friendly blocks are designed to be strong and weather-resistant, reducing the need for frequent repairs or replacements, which in turn conserves resources.

- Waste Reduction: Many eco-friendly blocks are made using recycled materials like fly ash or crushed glass, helping reduce waste in landfills and the demand for raw materials.

Types of Eco-Friendly Hollow Blocks

There are several eco-friendly hollow blocks options available, each with unique materials and production processes that contribute to sustainability.

1. Fly Ash Hollow Blocks

Fly ash, a by-product from coal-burning power plants, is a common material used in eco-friendly hollow blocks. These blocks are not only affordable but also contribute to reducing industrial waste. Fly ash hollow blocks are lightweight, durable, and have superior insulation properties.

- Advantages:

- Reduced carbon footprint by using industrial waste.

- Better thermal insulation, leading to energy savings.

- High strength, making them suitable for both residential and commercial buildings.

2. Recycled Aggregate Hollow Blocks

Recycled aggregate hollow blocks are made by using crushed construction debris, glass, or other recycled materials instead of raw natural aggregates. This reduces the need for mining and helps divert construction waste from landfills.

- Advantages:

- Reduces the environmental impact of mining.

- Helps recycle waste materials and contributes to a circular economy.

- Lighter and easier to transport, saving on energy costs.

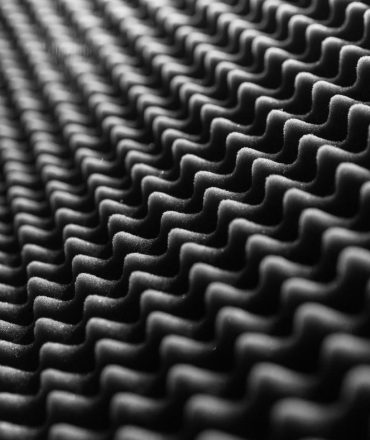

3. Cellular Lightweight Concrete (CLC) Blocks

Cellular Lightweight Concrete (CLC) blocks are made by adding foam to the concrete mixture, creating air pockets inside. These blocks are known for their light weight and excellent insulation properties, which improve energy efficiency in buildings.

- Advantages:

- Reduced weight makes them easier to handle and transport.

- Exceptional thermal insulation properties, reducing energy consumption.

- More affordable and easier to produce compared to traditional concrete blocks.

4. Geo-Polymer Hollow Blocks

Geo-polymer concrete uses industrial by-products such as fly ash, slag, and other waste materials to replace traditional cement in block production. Geo-polymer hollow blocks are highly durable, fire-resistant, and have a much lower carbon footprint than conventional concrete.

- Advantages:

- Drastically reduces CO2 emissions in production.

- Highly durable and resistant to fire and corrosion.

- Utilizes industrial waste, promoting sustainability.

Eco-Friendly Manufacturing Practices

The production of eco-friendly hollow blocks incorporates several key practices that minimize environmental impact:

1. Energy-Efficient Production

Manufacturers of eco-friendly blocks focus on energy efficiency in their production processes. This includes the use of energy-efficient machinery, renewable energy sources, and optimized production techniques that reduce overall energy consumption.

2. Low Carbon Footprint Materials

Using low-carbon materials like fly ash or recycled aggregates is essential in reducing the environmental impact of building materials. These materials not only reduce emissions but also help minimize waste, promoting a more sustainable construction process.

3. Water Conservation

Eco-friendly block manufacturers often employ water-saving techniques, such as reusing water during production. This helps reduce the strain on freshwater resources and ensures that the manufacturing process is more sustainable.

How Motherland Concrete Logistics is Leading the Way

Motherland Concrete Logistics is a leader in providing eco-friendly construction materials, including high-quality eco-friendly hollow blocks. Their commitment to sustainability has made them a trusted partner in the construction industry. Here’s how Motherland Concrete Logistics stands out:

Sustainable Sourcing

Motherland Concrete Logistics ensures that all materials used in their eco-friendly hollow blocks are responsibly sourced. Whether it’s fly ash, recycled aggregates, or other sustainable materials, the company prioritizes environmental responsibility throughout the sourcing process.

Advanced Manufacturing Techniques

To further reduce environmental impact, Motherland Concrete Logistics employs advanced manufacturing technologies that are energy-efficient and designed to minimize waste. Their production processes are optimized to ensure that every block produced has the least possible environmental footprint.

Innovation in Green Building Solutions

Motherland Concrete Logistics is continually exploring innovative solutions to enhance the sustainability of their products. By investing in research and development, the company stays ahead of the curve in offering new eco-friendly hollow blocks options that meet the evolving needs of sustainable construction.

Efficient Delivery and Logistics

In addition to sustainable manufacturing, Motherland Concrete Logistics also focuses on minimizing the environmental impact of their logistics. The company uses energy-efficient transportation methods and advanced logistics management to ensure that products are delivered with minimal energy consumption.

The Growing Demand for Eco-Friendly Hollow Blocks

As the construction industry increasingly embraces sustainability, eco-friendly hollow blocks are becoming more widely adopted. Their benefits go beyond energy efficiency—they also help create healthier, more resilient buildings. Here are some areas where eco-friendly blocks are making a significant impact:

1. Green Buildings

The demand for energy-efficient and sustainable buildings is growing. Eco-friendly hollow blocks are a key component in green building projects, as they help reduce energy consumption while offering durability and strength.

2. Sustainable Urban Development

With rapid urbanization, there is a need for sustainable construction materials that can support large-scale development. Eco-friendly hollow blocks are ideal for use in residential, commercial, and public infrastructure projects, helping create more sustainable cities.

3. Affordable Housing

The affordability of eco-friendly hollow blocks makes them a great option for affordable housing projects. These blocks not only reduce construction costs but also help create energy-efficient homes that are cheaper to maintain over time.

Conclusion

The growing need for sustainable construction materials has led to the rise of eco-friendly hollow blocks as a preferred option for modern building projects. Whether it’s fly ash, recycled aggregates, or cellular lightweight concrete, these blocks offer a range of environmental and practical benefits. Companies like Motherland Concrete Logistics are playing a crucial role in providing these sustainable solutions and promoting eco-friendly construction practices. By choosing eco-friendly hollow blocks, we can reduce the environmental impact of buildings and move toward a more sustainable and resilient future.

I