In the world of construction, the choice of materials significantly impacts not only the structural integrity but also the environmental footprint of a project. One innovative material that has gained traction is the lightweight hollow block. This article explores the benefits, applications, and significance of lightweight hollow blocks, while highlighting how Motherland Concrete Logistics plays a crucial role in distributing this effective solution.

Understanding Lightweight Hollow Blocks

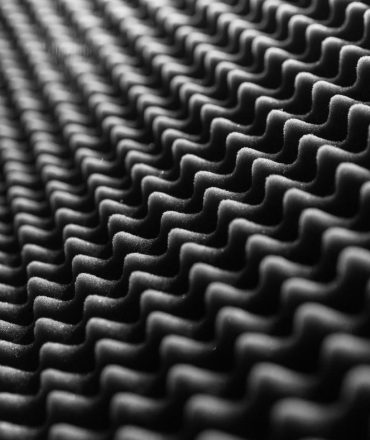

Lightweight hollow blocks are designed with air pockets, making them significantly lighter than traditional concrete blocks. This reduction in weight does not compromise their strength; in fact, it often enhances their thermal and acoustic insulation properties. As construction practices evolve, the demand for materials that are both efficient and sustainable has led to the increased popularity of lightweight hollow blocks.

Advantages of Lightweight Hollow Blocks

1. Reduced Weight and Increased Handling Efficiency

One of the primary advantages of lightweight hollow blocks is their reduced weight. This characteristic not only makes them easier to transport but also simplifies the installation process on-site. Builders can handle these blocks with less manpower, which leads to lower labor costs and faster project completion times.

2. Enhanced Thermal Insulation

Lightweight hollow blocks provide excellent thermal insulation. The air pockets within the blocks act as barriers to heat transfer, helping to maintain a stable indoor temperature. This feature is particularly beneficial in regions with extreme temperatures, as it reduces the need for additional heating or cooling, thus lowering energy costs.

3. Sound Insulation

In addition to thermal benefits, lightweight hollow blocks also offer sound insulation properties. The design of these blocks minimizes sound transmission, making them an ideal choice for residential buildings, schools, and commercial spaces that require privacy and quiet.

4. Eco-Friendly Material

Sustainability is a growing concern in the construction industry. Lightweight hollow blocks are often made from recycled materials, which significantly reduces their carbon footprint. By choosing these blocks, builders can contribute to environmentally friendly construction practices.

5. Cost-Effective Solution

While the initial investment in lightweight hollow blocks may be slightly higher than traditional blocks, the long-term savings are substantial. The reduced weight leads to savings in transportation costs, while their insulation properties can lower energy bills over time.

Applications of Lightweight Hollow Blocks

Residential Construction

Lightweight hollow blocks are increasingly being used in residential projects. Their insulation properties help homeowners achieve energy efficiency, while their lightweight nature makes them easier to handle, particularly for DIY projects.

Commercial Buildings

In commercial construction, the use of lightweight hollow blocks can lead to significant time and cost savings. Their sound insulation properties make them ideal for office buildings, hotels, and retail spaces where noise control is essential.

Infrastructure Projects

Infrastructure projects, such as bridges and tunnels, can also benefit from lightweight hollow blocks. Their strength-to-weight ratio allows for innovative designs while maintaining safety standards.

The Role of Motherland Concrete Logistics

When it comes to sourcing and distributing lightweight hollow blocks, Motherland Concrete Logistics stands out as a leading provider. Their commitment to quality and sustainability aligns perfectly with the growing demand for eco-friendly construction materials.

Efficient Distribution Network

Motherland Concrete Logistics boasts an efficient distribution network that ensures timely delivery of lightweight hollow blocks to construction sites. This efficiency is crucial for maintaining project timelines and minimizing delays.

Quality Assurance

Quality is paramount in construction materials. Motherland Concrete Logistics ensures that all lightweight hollow blocks meet industry standards. This commitment to quality guarantees that builders receive reliable products that contribute to the overall integrity of their projects.

Expertise in Sustainable Solutions

With a focus on sustainable practices, Motherland Concrete Logistics actively promotes the use of lightweight hollow blocks. They provide valuable resources and expertise to builders looking to make eco-friendly choices.

Challenges and Considerations

While lightweight hollow blocks offer numerous benefits, there are challenges to consider. Builders must ensure proper handling and installation to avoid any structural issues. Additionally, local building codes and regulations must be adhered to when using these materials.

Conclusion

The construction industry is evolving, and the shift towards lightweight materials like lightweight hollow blocks is a testament to this change. With advantages ranging from reduced weight and enhanced insulation to sustainability, these blocks are becoming a preferred choice for builders.

Motherland Concrete Logistics plays a vital role in this transition by providing quality lightweight hollow blocks and ensuring efficient distribution. As more builders recognize the benefits of lightweight hollow blocks, the demand for such materials will only increase, paving the way for a more sustainable future in construction.

Incorporating lightweight hollow blocks into construction practices not only enhances efficiency and reduces costs but also contributes to a greener planet. By choosing this innovative material, builders can lead the charge towards a more sustainable construction industry.