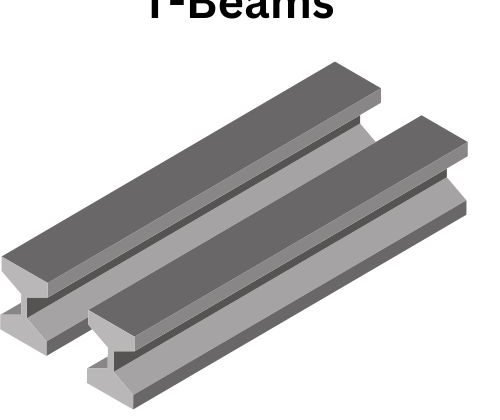

In today’s rapidly evolving construction landscape, the choice of materials plays a pivotal role in determining both the cost and sustainability of a project. Among various options, T-beams for sustainable building stand out as a vital component for contractors, architects, and homeowners alike. This article delves into the importance of utilizing T-beams, with a particular focus on how Motherland Concrete Logistics can streamline the process.

The Importance of T-Beams for Sustainable Building

The construction industry is constantly under pressure to minimize expenses while maintaining high standards of quality and safety. T-beams for sustainable building provide a solution to this challenge. By opting for these efficient structural elements, builders can significantly reduce overall project costs while ensuring durability and sustainability.

Choosing T-beams can lead to substantial savings during both the construction phase and the life cycle of the building. Their unique design allows for efficient load distribution, resulting in less material usage without sacrificing strength.

Types of T-Beams for Sustainable Building

Several types of T-beams for sustainable building are gaining popularity due to their affordability and practicality. Here are some noteworthy examples:

1. Precast T-Beams

Precast T-beams are manufactured in a controlled environment and transported to the construction site. This method not only ensures high quality but also minimizes on-site labor costs and construction time, resulting in significant savings.

2. Composite T-Beams

Composite T-beams combine different materials, such as concrete and steel, to create a stronger, more durable product. This hybrid approach optimizes resource use, making them a cost-effective choice for various building applications.

3. Reinforced T-Beams

Reinforced T-beams, designed with additional steel bars or mesh, enhance structural integrity. This durability means less frequent repairs and replacements, aligning perfectly with sustainable building practices.

4. Lightweight T-Beams

Lightweight T-beams offer an efficient solution for sustainable construction. Their reduced weight allows for easier handling and transportation, contributing to lower carbon emissions during the construction process.

The Role of Logistics in T-Beam Distribution

One often-overlooked aspect of achieving cost-effectiveness in construction is logistics. Efficient material distribution can significantly impact the overall cost of a project. This is where Motherland Concrete Logistics comes into play.

Streamlined Distribution

Motherland Concrete Logistics specializes in the transportation of construction materials, ensuring that builders receive their T-beams promptly and efficiently. By minimizing delays and ensuring the right materials arrive on time, they help contractors maintain project timelines and budgets.

Cost Savings Through Efficiency

Efficient logistics not only save time but also reduce costs. By optimizing delivery routes and employing advanced tracking systems, Motherland Concrete Logistics ensures that materials, including T-beams, are delivered where and when they are needed. This level of efficiency is crucial for keeping projects on budget, making it a key component of the overall strategy for utilizing T-beams for sustainable building.

Environmental Impact and Sustainability

In recent years, sustainability has become a major focus in construction. Utilizing T-beams for sustainable building can enhance a project’s appeal and marketability. These structural elements often have a lower carbon footprint compared to traditional options, making them an attractive choice for environmentally-conscious builders.

Green Certifications

Many T-beam products now come with certifications that indicate their sustainability. Materials sourced from renewable resources or those that are recyclable at the end of their life cycle can help builders achieve both cost-effectiveness and compliance with environmental standards.

Long-Term Benefits

Investing in T-beams for sustainable building can yield long-term benefits. Although the initial cost may be similar to conventional materials, the savings in energy consumption, maintenance, and potential tax benefits can lead to significant overall savings.

Challenges in Choosing T-Beams

While the advantages of T-beams for sustainable building are clear, challenges still exist. The selection process can be overwhelming, with a multitude of options available in the market. Builders must carefully evaluate materials based on their properties, availability, and suitability for specific projects.

Quality vs. Cost

One of the most significant challenges is balancing quality and cost. While it may be tempting to opt for the cheapest materials, this can lead to higher long-term expenses due to maintenance and replacement. It’s essential to conduct thorough research and possibly consult experts to find T-beams that meet both quality standards and budget constraints.

Supply Chain Disruptions

Another issue that can affect the cost-effectiveness of T-beams is supply chain disruptions. Global events, trade policies, and natural disasters can impact the availability and price of materials. Builders must stay informed about market conditions and be adaptable in their sourcing strategies.

Conclusion

Selecting T-beams for sustainable building is crucial for anyone involved in the construction industry. Not only do these materials help reduce costs, but they also contribute to sustainable building practices and long-term savings. Collaborating with reliable logistics providers like Motherland Concrete Logistics can further enhance the efficiency of material distribution, ensuring that projects remain on schedule and within budget.

By making informed choices and embracing innovation, builders can navigate the complexities of modern construction while achieving significant savings. As the industry continues to evolve, the importance of T-beams for sustainable building will only grow, making them a vital consideration for future projects.